Meet the experts

Peter Holland, sales manager at Exel Composites UK

Rob Hewison, technical manager, Composite Centre, University of Sheffield AMRC

Iain Bomphray, director of the Lightweight Manufacturing Centre (LMC), part of the National Manufacturing Institute Scotland (NMIS)

Jon Bridges, CEO, Velocity Composites

What trends and customer requirements are driving developments in composites?

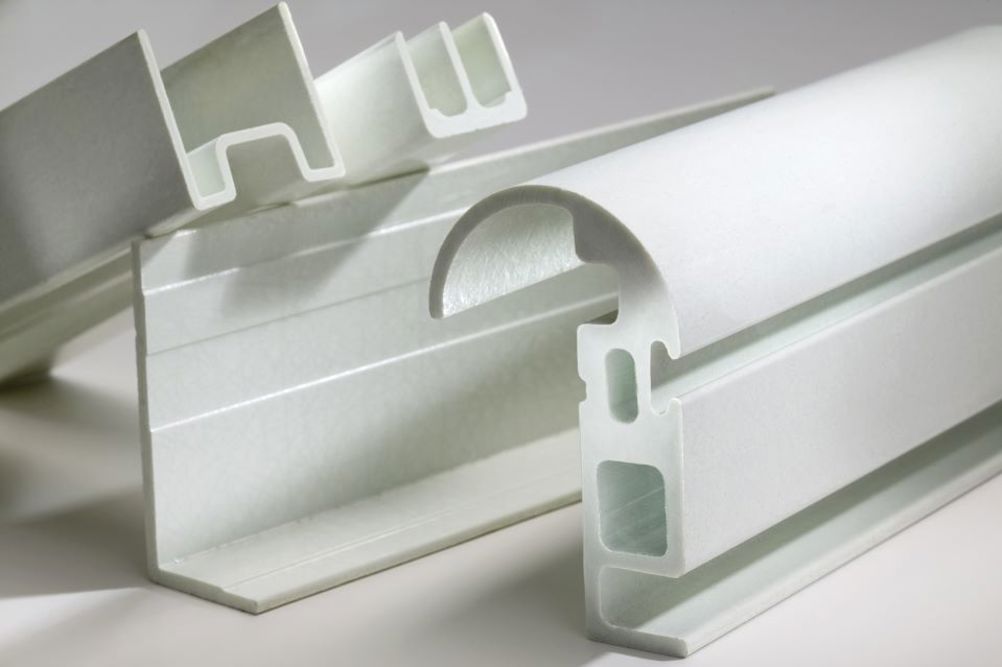

PH: For the UK, our biggest markets are construction and infrastructure, so customers here need window and door profiles that balance thermal efficiency without sacrificing high mechanical strength. We’re also seeing an increase in the demand for fire retardancy, particularly for construction and rail systems. However, across the industry, trends include the need for lightweight, corrosion resistant composites, with the strength comparable or better to steel and aluminium needed for long lifecycles. These properties are critical for our customers, who are now looking to make more sustainable products that don’t need frequent maintenance.

IB: A key trend and increasing focus point in composites is sustainability. One of the biggest challenges is developing impactful and cost-effective sustainable strategies, both in the creation of sustainable virgin materials and in dealing with end-of-life composites and in-process waste. Carbon fibre, for example, at its base, is a thermoplastic polymer derived from unsustainable oil products. However, there is an increasingly high volume of products manufactured with composites, particularly in the renewables industry and wind turbine blades, where lightness is directly related to performance. Scotland is also lagging behind the rest of the UK in terms of companies already engaging with composites and ,with a high proportion of private sector enterprises, it is important that we work with SMEs and make composites more accessible.

RH: Sustainability in all its guises is becoming one of the key elements to our research. The use of sustainable materials is only one part of this work. Making all of our processes as sustainable as possible and reducing the overall impact of manufacturing advanced composites is also a key theme. Advanced, high-performance composites may not in themselves appear to be the most sustainable products. But properly applied, and designed to be used as sustainably as possible, these materials are enabling significant sustainability improvements in products through extremely efficient lightweighting of structures. Automation of layup is also a key theme, through the use of weaving or braiding technologies, or through pick-and-place technologies, in particular an area we are calling 2D-to-complex-3D manufacture, using several different techniques to create a flat blank from which a complex component can be formed quickly and effectively using compression moulding or pre-forming techniques.

JB: Customers want cost efficiencies and supply security at a time of rising costs in the supply chain, environmental pressures and supply issues as we emerge out of the pandemic to more positive market conditions. There is an increasing need to reduce waste, make efficiencies through the manufacturing process and deliver to the highest quality standards. The UK aviation sector has set ambitious decarbonisation targets with reductions of 15 per cent by 2030, 40 per cent by 2040 and a commitment to reach net zero by 2050, greatly increasing the need for cost-efficient lightweight structures. While composites are leading the way in making aerospace lighter, stronger and greener, the same technology can be adapted and rolled out to alternative sectors so that efficiency benefits can be felt even wider.

How are your products or services helping customers?

IB: The LMC has three long-term funded programmes which are addressing the challenges of sustainability and accessibility through its Micro-Circular Economy strategy that enables both material and product manufacture. Our three programmes are: Future Fibre, Sustainable Composites and Reconfigurable Pilot Line. Future Fibre is a research lab for thermoplastic fibres, virgin polymers and composites, including those from sustainable sources. Sustainable Composites refers to end-of-life composite recycling and reformatting. Reconfigurable Pilot Line is the low-cost and agile integrated digital manufacturing system of cells to identify and fill production requirements between manually intensive and sophisticated, bespoke production lines.

PH: A customer will approach us with a challenge, and we will design a solution to meet their needs. This might involve adjusting the structure of the pultruded profile for better mechanical strength, optimisation of shape for efficient manufacture or advising on alternative resin selections or additives for chemical resistance or fire retardancy. Composites using glass and carbon fibres are very different to metals. Therefore, if a customer isn’t used to processing or designing their product with composites, we can offer the necessary advice and support. Furthermore, Exel combines a large manufacturing footprint and the expertise of a global company with the ability to offer local production and support from its Runcorn factory.

RH: Our larger customers, in particular those from the aerospace sector, are facing the challenge of manufacturing future aircraft at rates of 80 to 100 aircraft per month, compared with today’s requirements and maintaining the expected high-quality standards demanded by their sector. Currently these quality challenges are met by mostly manual layup, or relatively slow and expensive fibre placement processes. We also find that our composites focused solutions are beginning to spread across the entire AMRC group. As we develop the detailed new or improved composite processing requirements, the automation teams are challenged with streamlining the upstream and downstream processes.

JB: Our world class team of composites engineers understand the build process of our customers, and work to interpret and understand their requirements to offer proven, scalable and cost-effective supply chain management, kit cutting and logistics solutions to reduce operational costs and improve manufacturing throughput. Composites are already supporting sustainability and helping companies to achieve their low carbon goals by dramatically reducing component weight without impacting performance, enabling increased fuel/energy efficiency. Our services further ensure these composite materials are transformed into critical parts with minimal waste, through increased material utilisation and zero operating down-time at point of lay-up. We know that our process has to accommodate the normal demand variations our customers experience, and so we support our clients with dedicated kit supply at every step of the way.

What is the key product/technology for you currently, and how is it being applied?

PH: The key technology for us is our pultrusion manufacturing process. This is where fibres are uniformly guided and pulled together before being saturated with resin. The fibres are then pulled through a heated die, which cures the composite before the profiles are cut to the desired length at the end of the line. The process is highly automated, which ensures high volume output and a consistent quality because we can precisely control the fibre alignment. We can also manufacture continuous composite profiles up to several kilometres long, which are spooled.

IB: Our key project, the Reconfigurable Pilot Line, offers an infinite range of low cost and connected manufacturing technologies. This means that companies can come to the LMC not just for product development but also for a skeleton of the manufacturing line necessary to deliver cost efficient and impactful production of those products. An ecosystem where clients can workshop and refine their manufacturing processes and researchers can test their manufacturing technologies in an industrial environment. It's a Systems Engineering approach. In testing the production process, we can provide the data and analytics required for a business case and de-risk the process for engineers, management and investors alike.

RH: The manufacture of complex parts from ‘dry fibre’, as opposed to the more traditional ‘pre-preg’ manufacturing. The creation of a dry fibre structure suitable for a complex downstream infusion or RTM (Resin Transfer Moulding) based moulding process is at the forefront of this research. The ability to create complex, single-piece structures quickly with high levels of automation has enabled the likes of McLaren to lead the way in this work in the UK. We have a variety of research machines…that allow us to create very complex automated pre-forms from several processes in support of this drive for ever more complex structures to be manufactured in fewer pieces.

JB: Our proprietary digital technology eliminates risk by giving us real time information on customer demand, raw material stock, raw material order book and operational performance so we can understand any impacts of change in all its forms, and the investments we have made supports our whole customer base by allowing us to easily replan to drive efficiency. By their nature, composite raw materials we handle are un-cured, and so have a frozen storage life, and an ambient life which commonly is as short as 15 days, so it is important to effectively schedule and manage our kit production processes to ensure ambient life is maximised for our customers’ use. Indeed, using Velocity technology, we ensure there is total traceability of the materials and kits at every step, both in and out of the freezer store.

What products and technologies are having the biggest impact on composites?

IB: Connected automation and manufacturing our own materials from recycled composites are our primary goals today. Recycling composites involves energy efficient shredding and separation of resins and fibres. This recycled material is then reformatted into engineered materials with consistent and performant mechanical properties. This can also include dealing with manufacturing waste in composite production. As the process often involves the waste of high value materials, strategies to reprocess and reformat this waste into viable alternative materials are highly desirable. There are further incentives to create near-zero waste products if these materials are reabsorbed within the product in a useful way. By creating our own materials, we are in possession of extensive data on energy and CO2 consumption.

PH: I think it’s more a change in procurement attitudes that will impact the composites industry the most. Companies needing to source materials for their products are now starting to consider the whole life cost and the environmental impact of these materials, rather than simply buying whatever is cheapest. What’s more, continued investigations into the recycling of composite materials will also impact the industry. Exel Composites continues to work alongside several industry associations to investigate recyclability. Sustainable manufacturing policies are in place to ensure the company’s environmental footprint is kept at a minimum. We are setting sustainability goals and will continue to find ways to improve our sustainability footprint.

RH: As part of MASTRO, a European consortium, AMRC contributed significantly to the field of self-heating and self-sensing composites, leading to the ability for the material to begin to monitor its own condition through the acquisition of data on the material properties used in the manufacturing process. Self-aware materials that can detect and store information regarding their condition will have a significant impact on structural composites going forward. SHM (Structural Health Monitoring) applied in the right environments will allow conservative factors of safety currently employed in design to be reduced, due to the ability to monitor the component’s behaviour.

JB: Our real-time data-driven processes give us and our customers valuable information upon which to make decisions as we move forward. The raw materials used are expensive, often single sourced and have long lead times, with risk at every step of the process of the chain. The advantages of our bespoke technology ensure material order schedules are in-line with committed customer demand and material utilisation is maximised from our optimised nesting approach to such demand. Composite material waste is minimised through pro-active management of material life throughout our kit production and Just-In-Time kit delivery ensures minimal inventory at customer plants and full integration into their part manufacturing processes. Without this any changes to kit demand in the material lead time windows can have a significant impact on future material stock levels and performance.

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...