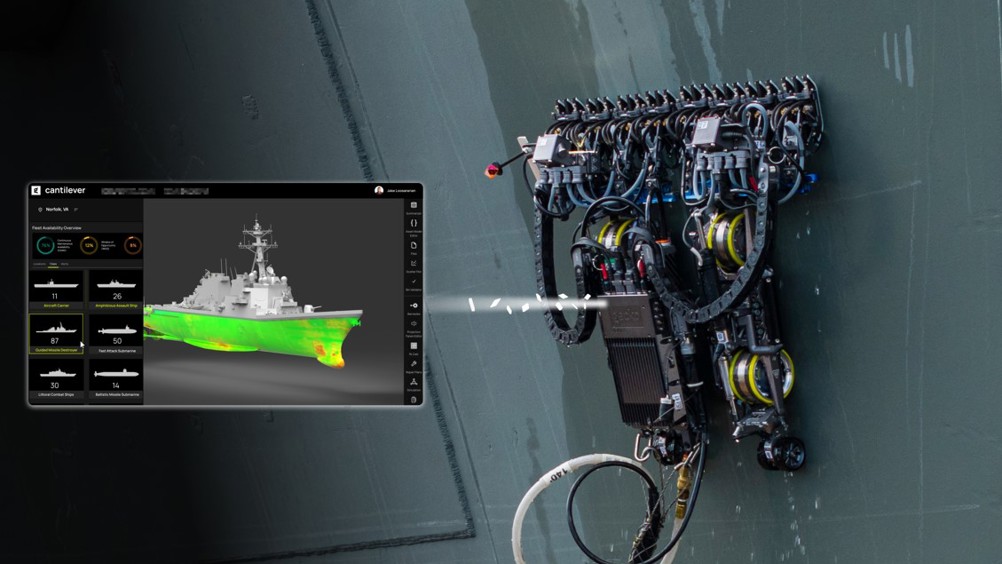

Interview with Gecko Robotics CEO Jake Loosararian

Gecko Robotics is on a mission to codify and optimise the world’s infrastructure. Andrew Wade spoke to founder and CEO Jake Loosararian.

The inspiration for Gecko Robotics came when founder and CEO Jake Loosararian was visiting a Pennsylvania power plant during his time at university.

“The problem for the plant was they were experiencing these really crazy shutdowns,” Loosararian told The Engineer. “About 40 per cent of the year they were having forced outages because of infrastructure failure.”

At one point in the tour, the plant manager explained that a worker had died on site the previous year while examining the plant’s boiler for defects. “I was kind of just like, dumbfounded, right? Like, this is 2012…and dudes are dying on ropes, trying to search for invisible defects,” said Loosararian. “And then I started thinking about, like, ‘Man, I wonder what else that we rely on, that’s made out of metal or concrete or whatever that’s been around for 100 years is going to start killing us?’”

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

CCC Report Finds UK Climate Targets Still Within Reach

In 1990 67% of the UK´s electricity came from coal-fired power stations and even without renewables the transition to gas was a major contributor to...