How did nuclear energy get so expensive? Arriving in the 1950s with the promise of being ‘too cheap to meter’, the technology has grown increasingly complex through the decades. At the same time, nuclear incidents over the years – from Windscale and Three Mile Island to Chernobyl and Fukushima – have precipitated increased safety and containment measures, further driving up costs.

The UK’s next generation of flagship nuclear generation – under construction at Hinkley and Sizewell – have acquired an unfortunate billing as the ‘world’s most expensive power plants’. Hinkley C’s current estimated construction cost has risen to nearly £33bn, and its strike price of £120 MWh (£92.50 in 2013, adjusted for inflation) is around four times that of new solar and wind.

Unlike most renewables, however, nuclear thrives on 24/7 operation, delivering baseload electricity around the clock. As such, it is widely agreed that nuclear will have some role in a future low-carbon energy mix, and its flexibility and high heat output mean it can deliver far more than just electricity. But how do we arrest the spiralling costs that have come to define new nuclear?

“Everybody says nuclear has to be part of the mix,” said David Landon, CEO of MoltexFLEX. “Our premise is that it has to be low cost.

“EDF are talking about better replication (of Hinkley) with Sizewell, that’s certainly their mantra. And I’m sure replication will take costs down. But I think it is a more fundamental level of cost that needs to come out, which is why personally I’m more convinced that if you really want to do that..if you’re going to be radical, you’ve got to change the technology.”

Established in 2020, Warrington-based MoltexFLEX is developing an entirely new nuclear reactor design, using two separate molten fluroide salts for the fuel and the coolant. Molten salt reactors (MSRs) have been researched in various forms for decades and have several hypothetical advantages over existing nuclear technologies. Chief amongst them is safety, as most MSRs operate in and around atmospheric pressure. This means they do not require the containment vessel, piping, and safety equipment of pressurised water reactors, which has significant knock-on effects for cost.

US military scientists first looked at MSRs as a power source for long-range bomber aircraft in the 50s, then wisely decided that having nuclear material strewn across a hypothetical crash site would be less than ideal. Sticking to land - for now – MoltexFLEX’s FLEX reactor is a thermal neutron stable salt reactor (SSR). Sister company Moltex Energy – operating in Canada since 2012 - is working on a fast neutron version SSR, which relies on a Waste To Stable Salt (WATSS) process that will recycle existing used nuclear fuel.

“In Canada, what we’re looking at is a waste burning reactor,” said Landon. “It uses many of the same principles – the salt fuel pin, the salt coolant – it looks the same in that way. It uses a similar approach to corrosion control, but it does start to diverge there, because the Canadian one is fast spectrum.

“We’ve got a site out there, we’ve got an operator, we’ve secured something like 60 million Canadian dollars’ worth of federal and state (funding), we’ve got SNC-Lavalin, aka Atkins, as a partner…so we’ve got a track record of being able to do those things in Canada…they’re a little way ahead, but I think we’ve made good progress in a short space of time.”

The two SSRs are designed to serve different purposes. The Canadian waste reactor can burn recycled and enriched nuclear fuel and is targeted at countries with existing nuclear infrastructure and spent fuel stockpiles. Conversely, the FLEX reactor uses unenriched uranium salt, meaning it could be adopted worldwide. FLEX is the best route for Moltex’s technology to be democratised around the world, according to Landon.

“The reason we made the very deliberate choice on 5 per cent uranium is to allow it to be deployed globally,” he said.

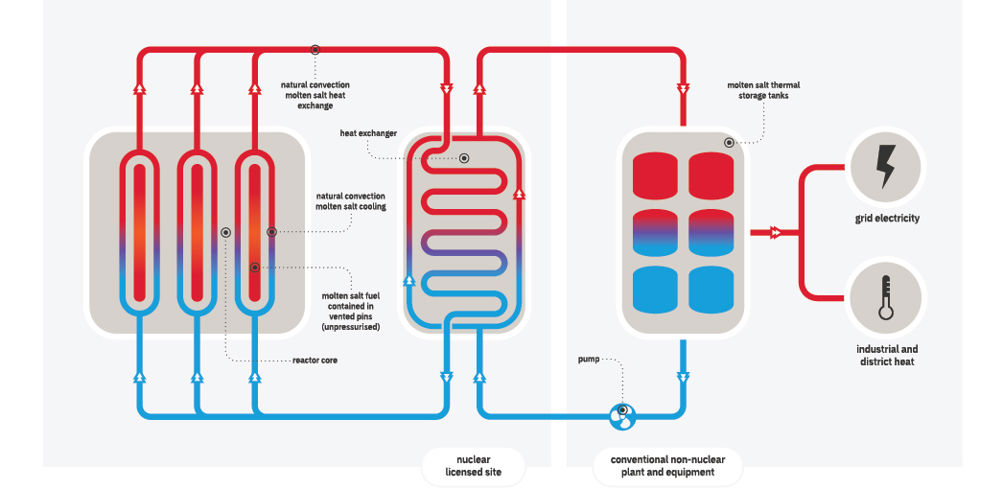

SSRs differ from other MSRs currently under development in that they restrict the highly radioactive fuel salt to tubes, similar to conventional reactors. A separate, non-radioactive molten salt transfers heat from the reactor core to heat exchangers. The whole process is driven by natural convection, which reduces complexity, negating the need for pumps, filters and other components that would come under severe stress in a radioactive environment. Separating the coolant salt from the fuel salt solves a lot of problems, allowing each to exist in tailored conditions.

“By spreading these two things out, we’re able to choose better additives for each environment,” explained Phil Quayle, lead chemist, laboratory manager and lead radiation protection supervisor at MoltexFLEX.

“You’ve got to do the right control for each of those two individual environments rather than trying to come up with a system which is able to cope with the massive quantity of cooling salt, and then trying to maintain the state of uranium and how it wants to play with all the other things.”

Corrosion management comes in the form of chemical rather than mechanical engineering, tweaking the common fluoride salts used for fuel and coolant. MoltexFLEX uses sacrificial metal to control redox in the salts, something that’s not practical for pumped MSRs as the metal would migrate to pump and valve surfaces. At the company’s lab in Warrington, testing is very much ongoing, but major progress has been made, according to Quayle.

“With the coolant side, particularly, I am satisfied,” he said. “We’ve started to look at evolution of fission products and things like that, how they interact. So that (fuel salt) is still on the discovery trail, but we’re moving at real pace, which I’m really pleased with.

“These are proven salts for industrial applications that have been used for a very, very long time. The dopants we’re adding, they aren’t exotic…and you aren’t relying on complex electronic methods for corrosion control and all this kind of other stuff.”

Safety is inherent throughout the design. The reactor has a passive residual heat removal system (RHRS) that operates continuously to remove 0.5 per cent of full reactor power, a small sacrifice to attain a completely passive system, according to MoltexFLEX. The RHRS uses the natural convection of air to cool the bottom, sides, and top of the reactor tank’s outer layer, where local temperatures are limited to 300-400°C. The upshot of the passive system is a huge reduction in expense in terms of safety redundancy and the structural components associated with it. According to Landon, the safety systems around gas-cooled reactors are a significant driver of cost.

“Highly radioactive, pressurised gas, it is expensive to contain and monitor,” he said. “And you know, if it goes wrong, you do get radiation exposure. The beauty of molten salt is, because it melts at 550C and it’s got huge thermal capacity, the pressure goes away. Our strategy has always been to make it inherently safe first, then passive safety controls, and try and really avoid active engineering controls if at all possible, which is what we’ve done.”

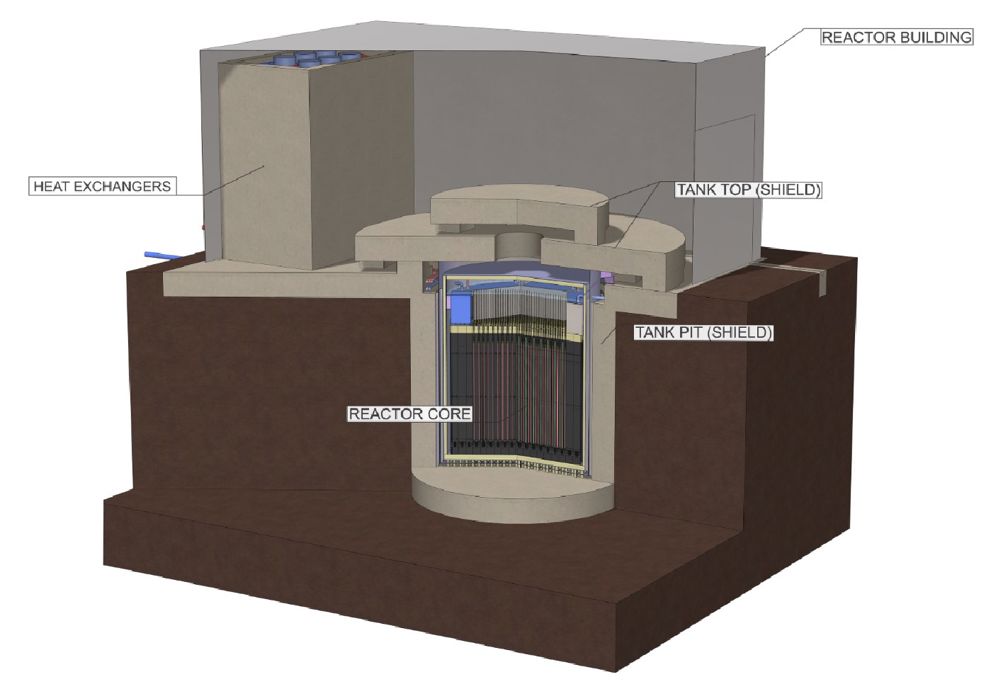

Above the reactor core and heat exchanger, the bulk of civil works will involve the concrete structure of the top shield. This component will slide on during commissioning, then slide back off for refuelling, which will need to take place every 16-25 years, depending on intensity of fuel burn.

“Essentially you’ve got a concrete structure about 6 metres diameter, 7 metres deep, top shield over the top of that,” said Landon. “After that, most it would be factory built.”

Modular off-site manufacturing should further reduce costs while maintaining quality. Each reactor will deliver thermal power of 40MW, which translates to 16MWe. Generating heat at 750°C, the FLEX is said to be 20 per cent more efficient than pressurised water reactors (PWRs), which allows the use of off-the-shelf turbines used in fossil-fuel power plants.

The levelised cost of electrical output is predicted to range from £27-£43MWh, depending on whether the technology is providing baseload or seasonal/peaking output. MoltexFLEX says the reactor can also deliver heat for as low as £8/MWhth, powering green industry, desalination or hydrogen production.

“Ultimately, you’ve got a very flexible source of heat,” said Landon. “You just need to decide on how you use it...decarbonising the grid is only about one-fifth of the problem. How do you do the rest?

“You can do things like high-temperature electrolysis if you’re going the hydrogen route. If you’re going to use ammonia, you can use cracking at the other end…and any sort of process plant producing hydrogen or ammonia really wants to operate 24/7 – they don’t like being turned on and off.”

The high-temperature output of the FLEX reactor also makes it an ideal partner for long-term, grid-capacity storage, something the global energy system increasingly requires. In light of this, MoltexFLEX is developing a thermal energy storage concept known as GridReserve. Essentially acting like a giant heat battery, GridReserve will feature tanks of molten chloride salt capable of storing heat for several days at temperatures of about 700°C. Paired with multiple FLEX units, GridReserve will add huge flexibility, allowing the reactors to continue running at full power while putting several times more power onto the grid for shorter durations, helping meet peak grid demands.

“The idea is that GridReserve - and whatever you then use that energy for - is outside the nuclear island, therefore you don’t need nuclear operatives,” said Landon. “A whole host of applications come out of that, from grid electricity, dispatchable baseload, down through hydrogen…water desalination.”

MoltexFLEX believes it can deliver this large-scale storage cheaper than almost every alternative technology, providing a levelised cost of electrical storage of roughly £50/MWh – around half that of alternatives like compressed air and hydrogen, and around a quarter of the cost of battery storage. The company is also considering fast-tracking GridReserve, coupling it with renewables while the FLEX reactor design is finalised and goes through certification.

“It’s half the cost of hydrogen, so that makes it very exciting as a storage medium,” said Landon. “That’s not to say you’d use GridReserve alone. For fast response, batteries are important, but not for long-term storage.”

“It’s a very simple design, we’ve got one-tenth of the systems of a PWR… the target remains to get a demonstrator reactor operational by the end of the decade

According to MoltexFLEX, the potential UK market for flexible generation and storage is around 100GW, equivalent to 625 FLEX reactors. Globally, the market is estimated at 4,000GW, translating to 25,000 reactors. And just as with Rolls-Royce and its small modular reactor (SMR), the export market is firmly in the sights. MoltexFLEX has already had preliminary engagement with Japan, Finland, Poland, Brazil, India and Egypt. Elsewhere, talks with the UAE are at a more advanced stage, MoltexFLEX discussing specific market applications with the country’s utilities operators. Landon says there is a possibility of providing a technology demonstration at COP28, set to be hosted in Dubai at the end of 2023.

“One of the reasons we’re doing the work in the UAE is the huge export potential,” said Landon. “We’re actually looking at a GridReserve type of project, a small-scale demonstration, with them…they’re very interested in desalination, and equally in storage. So at the moment we’re focusing on UK and UAE and then as we get investment, we’d expect to be going out into the wider world.”

While GridReserve could well be delivered soon at demonstration level, the road to approval for the FLEX reactor will be a much longer one. Nuclear safety and regulation being what it is, new technology and designs must be rigorously assessed before any sort of commercial roll out. The company is targeting GDA (Generic Design Assessment) approval over a 24-month process, beginning in 2024. This ambitious timeline should be aided by FLEX’s relative simplicity , according to Landon.

“It’s a very simple design,” he said. “We’ve got one-tenth of the systems of a PWR…which is why we believe that those timescales are reasonable for the technology…the target remains to get a demonstrator reactor operational by the end of the decade.”

Achieving that lofty goal will, says Landon, require some government support, though not necessarily the financial variety. Energy Secretary Grant Shapps was a recent visitor to MoltexFLEX’s Warrington site, and advanced nuclear is very much a part of the current net zero strategy. Creating a route to market will be vital for the technology to succeed, but the benefits for UK Inc are potentially enormous.

“One of our messages to government is we don’t necessarily need your money, but we need the right signals,” said Landon. “You know, we can solve this problem with technology and actually get a lot of prosperity out of doing it. My message would be to come and give us the right signals, tell us there’s a route here.”

If MoltexFLEX delivers even half of what it promises, it has the potential to be a genuinely transformative nuclear technology. The accelerated timeline – aided by the FLEX reactor’s simplified design – means we could see a commercial plant rolled out in the next ten years. According to Landon, there is no time to lose.

“If you look at what amount of energy needs to be built…I’ve been using the figure of one GW a day…in other words, a Hinkley Point would need to be built somewhere around the world every one or two days. That’s the scale of what needs to be done,” he said.

“Our ambition is to do this fast, because it needs to be done fast.”

McMurtry Spéirling defies gravity using fan downforce

Ground effect fans were banned from competitive motorsport from the end of the 1978 season following the introduction of Gordon Murray's Brabham...