The electricity sector is currently undergoing its biggest transformation for over half a century. The need to diversify electricity generation sources, bringing in new renewables, nuclear and fossil fuel plants to work with the existing generation infrastructure, the adjustments to the distribution network to allow these sources to contribute to the National Grid, and the development of smart grids and intelligent appliances to allow demand to be varied according to the availability and cost of power throughout the day, are all changing the way that electricity is generated, accessed and used.

However, there is another component to the electricity network which also needs attention, but which, at the moment, is not gaining a foothold: energy storage. This is going to be vital in the coming decades: according to a Technology Innovation Needs Assessment (TINA) from the Low Carbon Innovation Group published in August, the UK’s energy requirements in 2050 will include 7-59GW of total grid-connected electricity storage capacity.

There are two main reasons for this, according to an accompanying report from Imperial College’s Energy Futures Lab. The first is the increasing capacity of renewables in the energy landscape. As opponents of windfarms are quick to point out, the wind doesn’t blow all the time, so it’s important to be able to store excess electricity generated when it’s windy to even out the supply. The same applies to wave power, if it is developed as a large-scale technology and also, for slightly different reasons, to tidal power. Although the tides are highly predictable, they don’t necessarily occur when electricity is needed; the power generated by night-time tides, for example, would need to be stored.

The other reason is an upcoming increase in demand for electricity, the Imperial report says. As heating and transport systems are electrified in the coming decades, peak demand will rise sharply, and this ‘may lead to a significant degradation of generation infrastructure and electricity network assets’, leading to an increase in the cost of system integration; energy storage has the potential to reduce these costs.

There are several technologies, in various stages of development, that could be used for energy storage. In the UK, the largest grid-connected storage schemes at the moment use pumped storage, a variant on hydro-electric power: excess electricity is used to pump water from a low-level reservoir to a higher-level one, and when the electricity is needed back on the grid, the water is allowed to fall under gravity through a hydroelectric turbine.

The largest of these facilities is considered to be one of the UK’s current engineering marvels: Dinorwig, in the Welsh mountains of Snowdonia, also known as ‘Electric Mountain’. Consisting of 16km of tunnels inside the Elidir Fawr mountain, it took ten years to build and cost £425million in the 1970s, with 12million tonnes of rock excavated to create what was then the largest man-made cavern in Europe. The station has six 300MW generators, giving it a total capacity of 1.6GW.

And therein lies the problem: it’s only a small fraction of the storage the UK is projected to need, and there is little opportunity for further pumped storage of a similar size: it requires mountainous landscape, which is limited to a few parts of the country, and those are areas of natural beauty, rightly protected and very complex to build in. While there are smaller pumped storage facilities in Scotland and there have been plans to convert hydroelectric stations to pumped storage (and even a proposal to build a similar sized facility to Dinorwig in Exmoor, which was abandoned in the 1970s when plans for large numbers of nuclear power stations were shelved), it’s unlikely that pumped storage could meet UK grid-connected storage needs.

But the situation, even with intermittent wind-farms, isn’t as simple as it seems. It’s wrong to assume that every wind farm would need an associated energy storage system, insisted Steve Argent, senior consultant for major power projects at Arup. ‘It’s a grid issue,’ he explained. ‘The fact is that the UK is a very windy country, and although it’s quite true that one particular place might not have wind at any one time, leaving its wind turbines idle, it is very likely that another place will have plenty of wind.’ The storage issue isn’t so much backing up individual wind farms, he said: it’s making sure that the whole system has enough back-up to cope with averaged-out variations in wind that the country as a whole experiences.

Philipp Grünewald of the UK Energy Research Council and the Energy Futures Laboratory agrees. ‘I get quite worried when people talk about putting storage right next to a wind farm,’ he said. ‘You’d get much better results by smoothing supply out by linking wind farms in different parts of the country. For a start, you’d need to store much less electricity, because some will be generating while others aren’t; if each farm has its own storage, they’d have to be much larger. And it’s so much cheaper to build a distribution network than it is to build storage, the cost of the distribution losses around the network would be completely outweighed by the cost of building the extra storage locally.’

In fact, Argent said, the storage issue could neatly be turned on its head and looked at as an argument about demand, rather than supply. If demand could be matched to supply, for example through smart grids and intelligent appliances and industrial equipment which can alter their electricity usage according to how much is available, there would be no need for additional storage. ‘We’re talking about fridges that cool themselves down more when electricity is plentiful, then switch themselves off during peak time,’ he added.

However, as with most trade-offs, the actual situation will lie somewhere between. The establishment of smart grids and updating of applicances and equipment will balance out demand to a certain extent, but the grid will still need storage available.

But there’s still a problem with this: who will build, own and run these storage facilities? Grünewald said that this could be a major sticking-point. ‘I’ve been looking into this, and it’s a bit like a carousel,’ he said. ‘I asked the generators if they’d be willing to build storage capacity, and they don’t think it’s their responsibility; they think it’s a network function. And if you ask the network operators, they say that government regulations say that they’re not allowed to own generating capacity and storage, ironically, is classified as generating capacity; but if someone were to offer it as a contract service, such as a demand aggregator, they’d be happy to pay for it. So I spoke to them, and they said they’d be happy to offer the service, but they aren’t in the business of investing in capital-intensive equipment and the intermittency wasn’t their problem, so why didn’t I talk to the generators? And so around it goes.’

One problem might be that there is no organisation which can negotiate between different companies: if there’s a need to link four windfarms which are owned by different operators, who pays for the storage and who builds it? And then, Grünewald added, there’s the issue of what the contracts might look like, and how to handle competing interest. This is currently being investigated by Scottish and Southern Energy, he said, which is trying to set up a storage scheme in Orkney. SSE is providing an 11kW network access point, and inviting potential storage providers to build capacity alongside Kirkwall Power Station; the question of the commercial contracts, and how they can be set up to provide an incentive for the storage providers, could prove a sticking-point to whether anyone comes forward with a proposal.

Grünewald outlined the possible operational difficulties. ‘There might be a time when the wind is blowing strongly, and the storage system operator will want to charge up to use that excess wind,’ he said. ‘But that might happen when the demand is high, and the distribution operator will be saying please don’t charge, we need to discharge to avoid overstressing the grid.’ This conflict of interest could cause considerable problems, he said. ‘Different people need different things from storage, and without someone in overall charge, it could be quite difficult to negotiate that.’

The storage system looks like a classic market problem: storage systems will allow operators of intermittent generation capacity to utilise their equipment fully, and therefore maximise their potential earnings. But without some kind of overarching oversight, it seems that the problems might outweigh the solutions. The situation is developing, but as with everything associated with the UK’s energy network, the clock is ticking and the time to 2050, which once seemed so far away, is now uncomfortably close.

Battery of ideas

Electricity can also be stored chemically, of course, and battery systems are an obvious choice for energy storage systems. However, the problem of how to cram as much energy as possible into a small space while minimising the use of hazardous substances is just as pressing to those involved with grid-connected energy storage as it is to those developing batteries for electric vehicles.

One type of battery under consideration for grid-connected storage is the redox flow battery. These release energy through a reduction-oxidation reaction between two liquid electrolytes, which are held in separate tanks and pumped into a reaction chamber where they are separated by an ion-exchange membrane. This removes the link between the power density and the energy density of the system; the power density is determined by the size of the storage tanks, and the energy density by the size of the reactor.

These systems can switch between charge and discharge quite quickly, which makes them a flexible way to respond to rapid changes in demand and supply — handy for wind turbines, for example, where the speed of the wind is unpredictable. However, their dependence on pumps and the inherent losses where chemical reactions are involved reduces their efficiency. The systems are currently at an early demonstration phase, with some 20 companies attempting to produce systems that can store energy cheaper than $500/kWhr.

Another type of battery is the metal-air cell, where oxygen acts as one of the electro-active materials in the battery. Since oxygen does not have to be stored, the structure of the battery is simpler than an a two-electrolyte cell and has a higher energy density. Known since the mid-19th century, metal-air batteries consist of a porous carbon electrode, which holds the air that forms the cell’s cathode, separated from a metal anode by an electrolyte. They are now the subject of research because they have the potential for the highest specific energy of any battery technology.

Most current research centres around zinc-air and lithium-air systems. Lithium-air systems have a very high energy density, but the lithium needs to be protected from water, making them more complex and expensive to build. Zinc-air systems are cheaper and safer for the environment, but hold less energy.

Metal-air batteries are currently in lab-based R&D, with efforts to improve their capacity and their resilience: current technologies lose their capacity after around 50 charge-discharge cycles.

Gases to grid

Using excess energy to generate a fuel is receiving increasing amounts of attention. Teesside firm Air Fuel Synthesis earned headlines last month with a process that combines CO2 in the air with hydrogen generated by electrolysis to produce a hydrocarbon; in the US, a spin-off from Princetown University, called Liquid Light, is attempting to commercialise a technique developed in the 90s to generate methanol from atmospheric carbon dioxide; while in Iceland, Carbon Recycling International’s CO2-to-methane plant has been operating for almost a year.

These technologies have been touted as a method for reducing the CO2 in the atmosphere as an alternative to carbon capture and storage; however, as burning the fuel they produce re-releases the CO2 to the atmosphere they are perhaps better seen as a method of energy storage.

Sheffield-based ITM Power makes this link explicit, promoting its system of hydrolyser stacks which generate hydrogen from water as a method of storing megawatt-levels of electricity. The company, which is involved with the EcoIsland project on the Isle of Wight claims to have produced systems which can compress, store and dispense hydrogen at 350bar, which can be used as a vehicle fuel or a energy-storage medium for electricity generation via combustion or in a fuel cell. The company is running a project called GridGas which envisages using excess electricity from wind farms to split water, storing the hydrogen generated by electrolysis and selling it onto the gas network when demand rises.

Two other techniques, compressed air storage and cryogenic air technology, work in a similar way, but rather than using the excess electricity to generate a fuel, they use it to compress or cool air. In compressed air storage, currently under consideration for wide-scale implementation in the US, the air could be stored within depleted gas wells and underground caverns; cryogenic technology stores liquefied air in refrigerated vessels. In both cases, the energy is released by allowing the pressurised or liquefied air to return to atmospheric conditions and release its stored power through a turbine to regenerate the stored electricity.

Spinning around

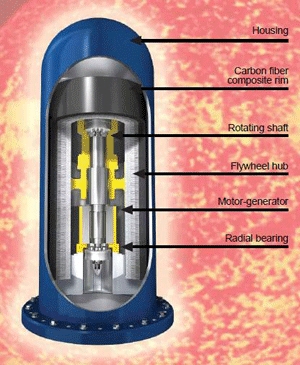

Used for centuries to store kinetic energy, flywheels are now being considered for large-capacity energy storage owing to developments in materials science and bearings technology. The basic principle is simple — a heavy rotor is connected to an electric motor, which accelerates its spin when energy is available for storage; conversely, slowing the wheel down releases energy. Companies such as Beacon Power in the US, and Flybrid and and Williams Hybrid Power in the UK, have developed carbon fibre-composite wheels inside vacuum chambers, supported by low-friction bearings (using magnetic levitation, in Beacon’s case), to develop systems which can store large amounts of energy and release it quickly without losing energy to friction.

Current flywheels designed for grid-connected storage are rated at 250kW for 10-15min, or 500kW for 36 seconds. The largest installed capacity so far is a 20MW facility in New York State, which is designed to regulate the frequency of the AC electricity supply. Frequency drops when demand exceeds supply and vice-versa, which can lead to blackouts, so the plant acts as a ‘throttle’ to balance supply and demand and keep the frequency constant. The plant , which was installed last year by UK contractor Mott McDonald, uses 200 1.3tonne flywheels. However, earlier this year Beacon declared bunkruptcy and was forced to sell the plant back to the US Department of Energy, which had lent it $43million to develop the technology.

Flybrid and Williams both developed their designs as components for KERS in Formula 1, and both are being used by automotive companies to store power in hybrid cars. However, interest for larger systems, for example for buses, trains and trams, and for static systems is high: the companies are developing static flywheels to be connected to generators to store energy for developing-world communities, for example. It would be only a short jump and a scale-up to transform this into a system for grid-connected energy storage.

Deep Heat: The new technologies taking geothermal energy to the next level

No. Not in the UK. The one location in the UK, with the prospect of delivering heat at around 150°C and a thermal-to-electrical efficiency of 10-12%,...