Category: Automotive

Headline Sponsor: Ejot

Project: Universal Battery Recycling System

Partners: Recyclus Group, University of Birmingham

Increased electrification is one of the key tenets upon which a net zero future must be built. But the transition to electric power from fossil fuels inevitably means a surge in reliance on batteries, particularly when it comes to transport.

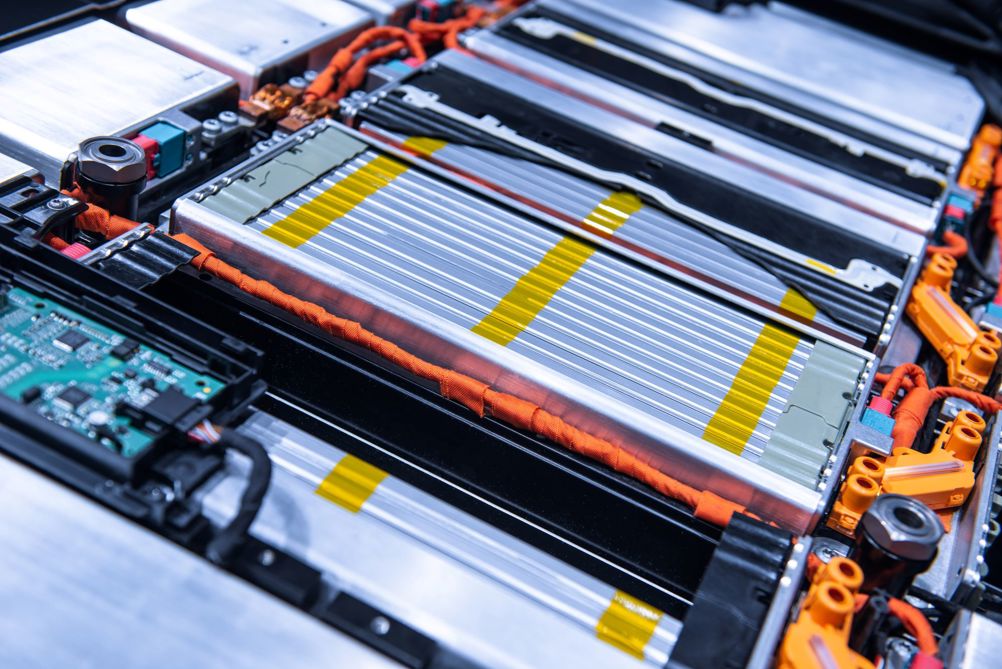

Since 2010, the lithium-ion (Li-ion) battery market has grown from 20 GWh to pass more than 1 TWh for the first time in 2023. By 2030, the market is expected to reach 4.7 TWh. Global lithium demand is forecast to reach 1.5 million tonnes by 2026. And while the Li-ion market soars, a major wave of EV battery waste is set to hit, with first generation EVs reaching end-of-life. Establishing methods to deal with these waste streams has therefore become a necessity, for both the automotive sector and beyond.

This year’s C2I winner in the automotive category presents a novel solution to the growing problem of Li-ion waste. Developed by the Recyclus Group in partnership with the University of Birmingham’s Advanced Materials & Processing Laboratory (AMPLab), the Universal Battery Recycling System (UBRS) is a mobile, truck-based platform capable of shredding and recovering materials from any type of Li-ion battery.

“Recyclus and University of Birmingham (UoB) are working together to create the first mobile battery recycling system capable of safely handling any type of EV and lithium-ion battery from all areas of industry,” said Robin Brundle, Director of Recyclus.

“The Universal Battery Recycling System (UBRS) will offer a reliable, cost-effective, automated process for the safe and environmentally friendly recycling of EV and lithium-ion batteries across the UK. The collaboration utilises Recyclus’ combined 75 years’ experience in recycling, shredding and mineral processing alongside UoB’s 30 years’ experience in design and manufacturing.”

UBRS is based on Recyclus’ existing LiBatt industrial-scale Li-ion battery recycling plant in Wolverhampton, which is capable of recycling 8,300 tonnes of lithium-ion per year. The enclosed system will use a gated infeed chamber and a series of sealed outfeed chutes to feed separated materials into collection bins.

Initially shredding the Li-ion batteries, UBRS will then separate the cells into five recyclable products: the ‘black mass’ of high value metals including lithium, manganese, cobalt and nickel; the electrolyte; ferrous metals (steel); non-ferrous metals (aluminium & copper); and light mixed fraction consisting of plastic, rubber and paper.

According to Kate Jermey, business engagement manager at the University of Birmingham, the collaboration will rely on additive and digital solutions to deliver on its objectives.

“This project will enable Recyclus Group and the University of Birmingham to respond to the current challenges around battery recycling infrastructure,” said Jermey. “(UBRS) will provide a viable and desperately needed solution to the issue of waste batteries, through the usage of Industry 4.0/ Additive Manufacturing Solutions to speed up systems design and deployment.”

Three truck size options ranging from 7.5 to 16 tonnes will be capable of dealing with up to 2,000 kilogrammes of battery waste per hour. Part of the collaboration has seen Recyclus working with Birmingham’s School of Metallurgy and Materials to design the cutting tools for UBRS.

“The project is led from Recyclus’ recycling facility in Wolverhampton, with computer systems, software, and in-house fabrication capability, whilst UoB’s School of Metallurgy and Materials laboratories will be used to design, optimise, and produce mobile plant cutting tools,” said Brundle.

“Recyclus plans to deliver the recycling trucks with three size options ranging from 7.5 to 16 tonnes which will be capable of processing between 500 and 2,000 kilogrammes per hour of lithium-ion batteries.

“These innovative mobile units will help accelerate the recovery of critical raw materials essential to the transition to electrification and significantly reduce the use of landfill. The project will implement a new industry standard that can benefit not just the UK, but around the world.”

While waste streams from the electric mobility sector – including scooters and e-bikes - are expected to provide the bulk of the work for UBRS, it is by no means the only source of Li-ion waste that needs to be tackled. Personal electronics represent another potential stream, while the massive growth in disposable vapes is fuelling both a plastic and e-waste crisis. A 2022 report led by the Bureau of Investigative Journalism suggested that two disposable vapes were discarded every second in the UK, containing enough lithium to make around 1,200 electric car batteries a year.

A circular solution is essential, but both knowledge and capability around Li-ion recycling are low. The Environmental Services Association (ESA) estimates around 200 waste fires each year are caused by Li-ion batteries each year in the UK, despite sending the batteries to landfill being illegal. The UBRS partners believe mobile units can take the recycling solution to the problem, accelerating the recovery of the critical raw materials essential to the transition to electrification, while at the same time significantly reducing the use of landfill.

“The rapid development of consumer goods such as vapes, handhelds, e-Bikes and the general transition to electric transport is already causing serious environmental issues,” said Brundle.

“The build-up of end-of-life Li-ion batteries over the coming years will create a battery waste tsunami that we need to prepare for by investing in the capabilities and capacity for large-scale battery recycling.”

In 2023, UBRS was awarded £1.96m Innovate UK funding, with the project set to run until 2026.

IET sounds warning on AI doll trend

I agree that we need to reduce cooling water demand for servers. And yes, generative AI consumes a large amount. But what about BitCoins? Their...