According to the NUS researchers, their new technique has enabled the direct conversion of CO2 from treated flue gas, a common by-product of industrial processes, into high-value multi-carbon (C2+) products.

Specifically, these C2+ products, such as ethylene and ethanol, are essential raw materials to produce everyday compounds such as plastics, polymers and detergents.

The researchers said that this advance could not only circumvent the need for high-purity CO2 but also repurpose a prevalent waste product, working towards closing the carbon cycle and reducing reliance on fossil fuels.

Traditionally, the process of transforming CO2 into a range of feedstocks for chemicals and fuels demands high purity-CO2, energy-intensive purification and high costs, according to the researchers.

The presence of oxygen impurities in flue gas often results in undesired side reactions, which can significantly reduce the efficiency of the CO2 reduction process.

The research team, led by Assistant Professor Yanwei Lum from the Department of Chemical and Biomolecular Engineering, the NUS College of Design and Engineering, aimed to avoid these challenges by integrating catalyst design with electrolyte selection.

In their recent study, published in Nature Communications, the researchers introduced a new method to design catalysts with ‘enhanced efficiencies’ for the electrochemical conversion of CO2.

Utilising this approach, they designed a nickel catalyst boasting exceptional performance for CO2 reduction, achieving an efficiency rate exceeding 99 per cent.

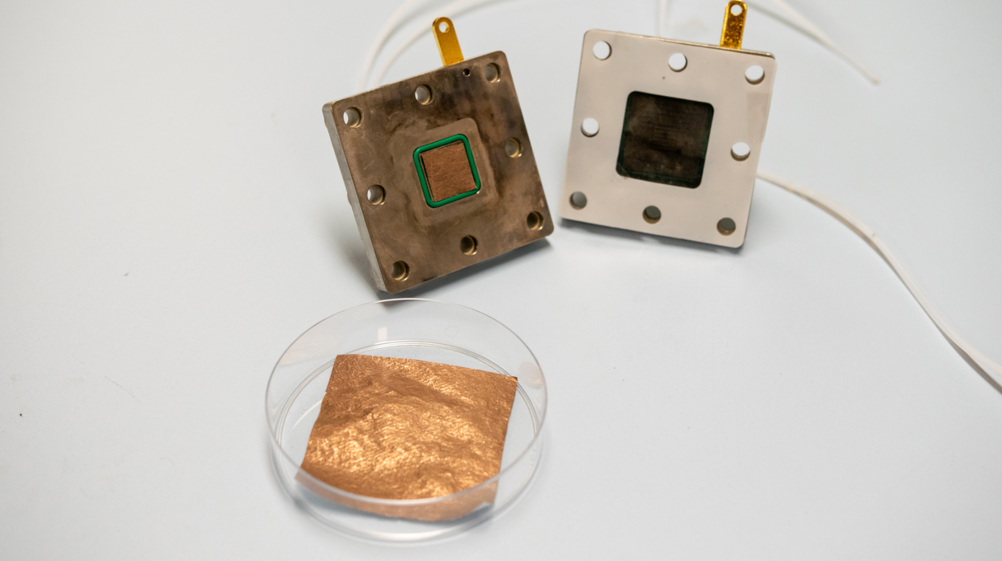

In a second study, published in the same journal on February 9, 2024, the NUS team designed a composite system by sequentially layering this nickel catalyst onto a copper surface.

“We found that integrating acidic electrolytes with this composite system significantly suppresses the undesired side reactions from oxygen impurities in flue gas,” Assistant Professor Lum said in a statement.

This system demonstrated comparable performance with systems that utilise pure CO2 as feedstock.

“The cost of purifying CO2 can amount to about USD $70 to $100 per ton, which can constitute about 30 per cent of the costs involved in converting CO2 to feedstocks such as ethylene through electrochemical means,” said Assistant Professor Lum.

“Our novel technique demonstrates a potential pathway for the development of efficient electrolysers for the direct conversion of CO2 in flue gas, using simple yet effective electrolyte and catalyst design strategies to advance integrated sustainability solutions.”

Looking ahead, the researchers said that this technique could be applied to synthesise other valuable chemicals, such as acetate and propanol which are used in the production of everyday products such as adhesives and disinfectants respectively.

“We are seeing strong interest from the industry and are currently in talks with some companies to further advance this research,” said Assistant Professor Lum. “Our goal is to enhance the energy efficiency and scalability of our system, moving beyond laboratory-scale experiments towards developing prototype reactors that can be applied in industrial settings.”

Arriva makes £300m tri-mode train order with Hitachi Rail

This development shows up the lack of a comprehensive nationwide network of electrified lines for passenger services and freight The glacial speed of...