From the development of hybrid-electric powertrains to the reinvention of the airship, no stone is being left unturned in the hunt for technologies that will help reduce the aviation sector’s carbon footprint. But whilst it’s certainly true that a range of different technologies will have a role to play, sustainable aviation fuels (SAF) look set to do most of the heavy lifting in the near future. We asked a group of leaders at the forefront of this rapidly growing sector about their technologies and how they see the SAF industry developing.

Meet the Experts:

James Hygate - CEO , Firefly Green Fuels

Paddy Lowe – CEO, Zero Petroleum

Sarah Ellerby - Chief Executive Officer, Nova Pangaea Technologies

Dr Gianluca Ambrosetti - CEO and Co-Founder, Synhelion

Alastair Hobday - Associate Fellow, Fuels and Lubricants, Rolls-Royce Plc

Explain your process and technology?

SE: Our patented process, REFNOVA, uses our proprietary Steam Assisted Rapid Pyrolysis (SARP) to convert non-food derived agricultural and wood residues into lignocellulosic ethanol which is crucial to producing SAF. This is a revolutionary technology, offering an efficient, clean and reliable process to produce advanced biofuels and co-products such as biocarbons – biochar and activated carbon. Our ‘second-generation’ biofuels are produced from residual and waste products, whereas ‘first-generation’ biofuels are directly produced from food crops.

Project Speedbird, a partnership between British Airways (BA), LanzaJet and Nova Pangaea Technologies, will then produce 102 million litres of Sustainable Aviation Fuel (SAF) per year, which BA intends to offtake to help power some of its flights. The first phase of Project Speedbird will deliver 750,000 tonnes of carbon reduction per year, the equivalent reduction in GHG of 26,000 domestic flights.

GA: Our technology uses solar energy to convert CO2 and water into solar fuels, a type of synthetic fuel. With our technology we can produce any type of hydrocarbon fuel….however, we decided to focus on the production of sustainable aviation fuels (SAF) because the aviation sector requires energy carriers with very high energy densities and electric batteries are still a long way away from reaching these energy density requirements. Our solar fuels meet the high requirements of the aviation industry in terms of energy density and can directly replace fossil fuels without any infrastructural adjustments.

PL: Zero produces synthetic jet fuel (SAF) and other synthetic fuels including gasoline (petrol) and diesel using a proprietary process we call DirectFT, which is our innovative spin on the century-old Fischer-Tropsch (FT) process.

The fuel that Zero produces is chemically identical to comparable fossil fuels currently being used in all sectors, meaning no modification or augmentation is required for existing engines or machinery to run on Zero fuel, and no further processing is needed to achieve the ideal fuel chemistry for each application.

JH: The technology we use to produce biocrude is called Hydrothermal Liquefaction (HTL). This process is particularly suitable for wastes like sewage sludge that contain a lot of water. After we process the sludge into crude, we then run it through our proprietary upgrading process to create our SAF. The fuel we produce has been shown in independent analyses to have an over 90% CO2eq saving versus fossil jet. Our process has been fine-tuned to work with sewage sludge, an abundant and continuously produced material. This means that through partnerships with utility companies, we will always have access to feedstock in predictable quantities.

What is the current status?

SE: We operate a demonstration facility and are currently undergoing engineering optimisation process ahead of our first-of-a-kind commercial facility which will most likely be sited in Teesside. In 2023…we received multi-million-pound investments from IAG and British Airways, in addition to £9 million government funding through the Project Speedbird partnership. We are confident of securing further significant investment in the coming months.

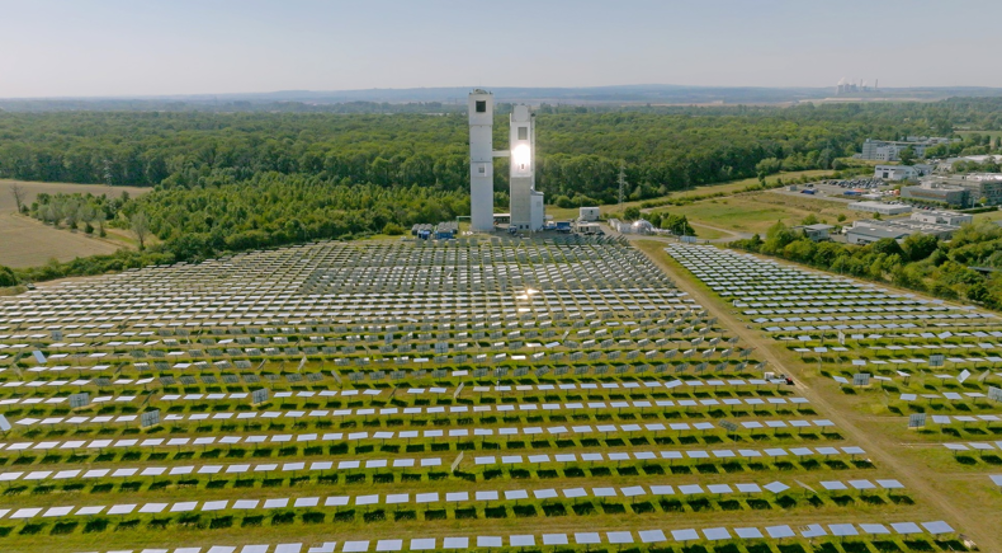

GA: We have completed the research and testing of our technology. We are currently building our first industrial-scale plant DAWN in Jülich, Germany. With DAWN, we want to demonstrate the feasibility of the technology on a large scale and provide fuel batches for relevant showcases. Swiss International Air Lines will be the first company to fly with our solar fuels. We plan to commission our first commercial plant in Spain in 2025. In December 2022, we closed our latest financing round of CHF 22 million. We are using this funding to scale and commercialise our technology. Among our investors are companies such as the SMS group, CEMEX, Eni, AMAG Group, and SWISS. Our next funding round is planned for 2024.

PL: Zero secured the Guinness World Records title of “first aircraft powered by synthetic fuel” in 2021 for the first flight powered entirely by synthetic fuel, achieved without making any changes to the engine or aircraft. The technology is already at a mature stage. After opening our Plant Zero.1 technology centre in Bicester Heritage near Oxford in June 2023, our team is in the process of evaluating locations across the globe for our first commercial-scale production: Plant Zero.2

It’s been estimated that SAF output will need to increase by a factor of 1,500 in order to reach targets set for 2050

This expansion has been made possible by our continued hiring of top-tier talent, as well as strategic partnerships with industry giants like Boeing, Rolls-Royce and ADNOC.

JH: We are currently preparing to seek fuel qualification from the standards authority ASTM. We expect to be ready to enter this assessment process later this year.

Up until now we have been hard at work producing and testing our fuel, as well as sending it to independent research facilities for testing. What we have found is that our fuel performs almost identical to fossil-derived jet fuel.

Our R&D has been ongoing since before 2020, and more recently has been supported by investment secured in early 2023 from the ultra-low-cost airline Wizz Air. Wizz also signed a 15-year offtake agreement with us for up to 525,000 tonnes of SAF over 15 years, with the potential to save 1.5 million tonnes of CO2eq. In addition, we are planning to seek series B funding this year.

What are the key challenges of scaling up production?

SE: Our biggest challenge is the biomass feedstock handling due to it being a continuous process. As we plan to deliver multi-site operations for our Speedbird project, site selection and logistics planning is critical for the amount of biomass handling required to deliver a full-scale facility.

With regard to the economic hurdles, the revenue certainty mechanism recently announced in Energy Bill is to be consulted on soon. This is good news for investors in providing clarity and certainty. However, the delay to the SAF mandate is disappointing – although NPT has strong relationships with investors, we need the government to recognise the importance of clarity in this area to encourage greater investment in the SAF production chain within the UK.

GA: Our technology is fully developed – scaling it to an industrial level and then to a commercial level is now our main priority. A major economic hurdle for us is the high capital requirement for the implementation of our technology, so what we really need is investment security. Our investors need to have security that their investment will pay off. Reliable political measures such as SAF quotas can help – something the European Union has introduced.

PL: Scalability is the question on everyone’s minds. It’s been estimated that SAF output will need to increase by a factor of 1,500 in order to reach targets set for 2050. While the focus will primarily be on increasing volume, it’s just as important to consider efficiency. All currently approved SAF pathways are required to have at least a 50 per cent blend with fossil fuels, giving them significantly higher carbon intensity than Zero’s fuel and merely reducing, rather than neutralising the problem. Our SAF is a 100 per cent synthetic blend meaning production can achieve carbon neutrality at scale without the need to purchase carbon offsets. Moreover our technology does not require extensive land use for agricultural feedstocks – our fuel is literally made from air and water using a 100% technology-based platform which has no limit in scale.

JH: We are very confident in our ability to scale up this technology to achieve a commercial output. However, like most GreenTech, SAF is a nascent industry and that presents challenges. It is never easy being the first to do something, and we are proposing an entirely new business model which will radically shift the paradigm.

Our entire focus is on realising our first commercial-scale facility. Once we can prove this technology to work at scale then we’ll be cooking on (bio)gas.

What are your ultimate ambitions for the technology?

SE: We believe that the UK has the experience and resources needed to become a global leader in the deployment of SAF facilities, which will boost the UK economy and create thousands of new, green jobs. Nova Pangaea Technologies want to be a catalyst for future SAF production, boosting growth in Teesside and across the UK.

In the long-term, we want to support decarbonisation of the aviation sector through deploying our technology globally, and significantly contribute to the estimated 61 billion gallons per annum of SAF demand by 2040.

GA: Our ambition is to substantially contribute to a net-zero transportation sector. As liquid fuels continue to be needed for travel, transportation, and freight, we need to shift to sustainable, cleaner alternatives. By 2033, we will target a commercial production capacity of 1 million tons of fuel per year, which corresponds to about half of Switzerland’s jet fuel demand. By 2040, we plan to ramp up production capacity to produce 40 million tons of solar fuel annually, enough to cover about half of Europe’s jet fuel demand.

PL: With a growing population and increasing standards of living, it is unlikely that humans will reduce our energy consumption anytime soon – we just need to find a different source of energy. Zero’s goal is to transition our linear system of energy consumption into a circular one, enabling society to access an indefinite supply of sustainable energy. We believe synthetic fuel will usher in a new Industrial Revolution to meet the challenges of our present moment, driving innovations in health, mobility, food cultivation and more, all without adding any CO2 to the atmosphere and with minimal impact on scarce resources such as land, water and rare metals.

JH: Our plan is to rapidly expand outwards once our first commercial facility comes online here in the UK. We see the potential for this technology to sit alongside existing water treatment infrastructure in many developed economies and over time we expect that we will be able to further adapt to meet the specific needs of different regions.

A view from Rolls-Royce

Alastair Hobday, fuels and lubricants specialist at Rolls-Royce, offers an engine manufacturer’s perspective on the SAF revolution

What are the engineering implications of a shift to 100 per cent sustainable aviation fuel?

The compatibility test programme we have undertaken has been a 2-year activity consisting of both ground and flight test engine evaluations running on 100% sustainable aviation fuel. This included engine models used in both the wide-body commercial aviation sector, and business aviation. The primary objective of this programme was to demonstrate that operation on neat SAF had no discernible impact on engine operability, handling and performance.

None of the engines encountered any problems running with the selected SAF variants, and furthermore overall engine behaviour on SAF across all tests was equivalent or better when compared to operation on conventional fuel. The results from this test campaign demonstrate that engine technology does not represent a barrier to 100% SAF adoption.

The Virgin 100% SAF transatlantic flight – a world first – that was completed in November was the culmination of this compatibility ‘campaign’, with the Trent 1000-powered Boeing 787 aircraft successfully completing the operation.

How is Rolls-Royce helping to drive the development and deployment of SAF?

We are working closely with a number of fuel producers on novel technology SAF pathways.

We have been active members of the ASTM International jet fuel standards committee for many years. Within the ASTM structure, there is an OEM technical panel which includes representatives from Rolls-Royce and other major aerospace companies such as Boeing, Airbus and GE. This group is responsible for technical qualification of new SAF pathways for the aerospace industry and the collaborative, non-competitive way in which it operates is critical to the timely adoption of new fuels technologies.

Rolls-Royce is also actively working with the so-called ‘Clearinghouse’ network. A Clearinghouse is essentially an independent body intended to generate fuel property data on new SAF pathways – this data is then shared with the OEM community for their technical consideration. The UK Government has supported the establishment of a UK Clearinghouse at Sheffield University to provide benefit and focus for the UK SAF industry. A Clearinghouse in the EU is also in plan.

Whilst technologies such as electrification and hydrogen are emerging, the need for gas turbine propulsion to support medium/long haul flight will remain for many years to come, and hence there will be a need for large quantities of SAF to support this

Since July 2022, Rolls-Royce has been using jet fuel containing 10% SAF component in its production and experimental engine testing at its main site in Derby, UK. This is provided via rail through a partnership with AirBP from their facility in the Southeast of England.

We also have technologies within our portfolio such as Small Modular Nuclear Reactors which could be key in producing so called ‘e-fuels’. The low carbon electricity from such a reactor would be utilised to ‘extract’ hydrogen from water by electrolysis – this can then be combined with carbon from either the atmosphere, or the efflux from an industrial process, to produce a liquid hydrocarbon, kerosene like-fuel.

What contribution is SAF likely to make to the sector’s shift to net zero?

SAF will play a key role in the shift to net zero for commercial aviation. Whilst technologies such as electrification and hydrogen are emerging, the need for gas turbine propulsion to support medium/long haul flight will remain for many years to come, and hence there will be a need for large quantities of SAF to support this.

Towards net zero 2050, SAF is anticipated, across a range of available energy transition scenarios….to account for slightly over two-thirds of the total fuel demand (and maybe up to 85%).

Near term, we need to encourage the ramp up of SAF because meeting net zero 2050 is not only about having the right solution mix by 2050, but implementing measures as early as possible to start mitigating the impact of adding CO2 in the atmosphere, with its lasting effect. To that end, we want to encourage the pursuit of bio-SAF now and ensure that the ground is prepared for a full SAF scale-up including e-SAF, which will require access to hydrogen feedstock and electricity in sufficient quantities.

Overall, the future for most mass-transport aviation segments is a gas turbine and we are ensuring that our products are (1) future-proof and compatible with most flavours of key fuels such as SAF (demonstrated in flight) and hydrogen (R&T ongoing) and (2) continuing to deliver improved efficiency such that they reduce demand on fuel and, by proxy, associated emissions.

PMI falls as manufacturers feel the squeeze

17 months or two and a half years - which is it?