Almost exactly 20 years after the retirement of Concorde, the dream of supersonic passenger flight remains very much alive. We spoke to some of The Engineers hoping to breathe new life into the concept and also asked some of the UK's leading independent researchers for their views on the feasibility of a new age of faster than the speed of sound flight.

Meet the experts

Troy Follak, Chief Technology Officer, Boom

Noris Tie, Chief Executive Officer, Exosonic

Dr Peter Thomas, head of the aerospace group and principal lecturer in aerospace engineering, University of Hertfordshire

Guy Gratton, Associate Professor of Aviation and the Environment, Cranfield University

What stage are you at in terms of aircraft development?

TF: Boom is currently in the conceptual design development phase of Overture [Boom's proposed supersonic airliner]. Key updates include new global suppliers for Overture and significant design progress on Symphony, the propulsion system for Overture. Earlier this year we shared high level architectures that highlight key systems including avionics, flight controls, hydraulics, fuel systems, and landing gear. Among the major systems highlighted, Overture’s fuel systems provide centre of gravity control during subsonic and supersonic operations, enable sustainable aviation fuel (SAF) compatibility and supply fuel to the engines. Triple redundant hydraulic systems provide reliable power for flight controls and mechanical systems, and Overture’s landing gear is compatible with international airport runways and taxiways.

NT: For our supersonic airliner, that development is in the conceptual design phases. We expect our aircraft to enter revenue service in the mid-2030s timeframe. For now, we’re focused on developing our UAV product line, starting with a testbed called EX-3M Trident, followed by our supersonic UAV called Revenant. These aircraft will help usher in autonomy in military aircraft to complete military-related missions, like air combat training, aerial targets, and others.

What wing and fuselage configuration will you use on your aircraft?

TF: Overture’s wing and fuselage configurations work in concert to minimise drag, allow integration of the engines below the wing, and support supersonic operation. The wing’s planform is shaped to minimise drag through the transonic and supersonic mission segments while still providing the necessary lift at low speeds. Spain-based Aernnova will design and develop the wing structure for Overture. The proprietary design of Overture’s contoured fuselage has a larger diameter toward the front of the aircraft and a smaller diameter toward the rear. Boom applied this design technique to minimise drag and maximise fuel efficiency at supersonic speeds.

What propulsion system will you use?

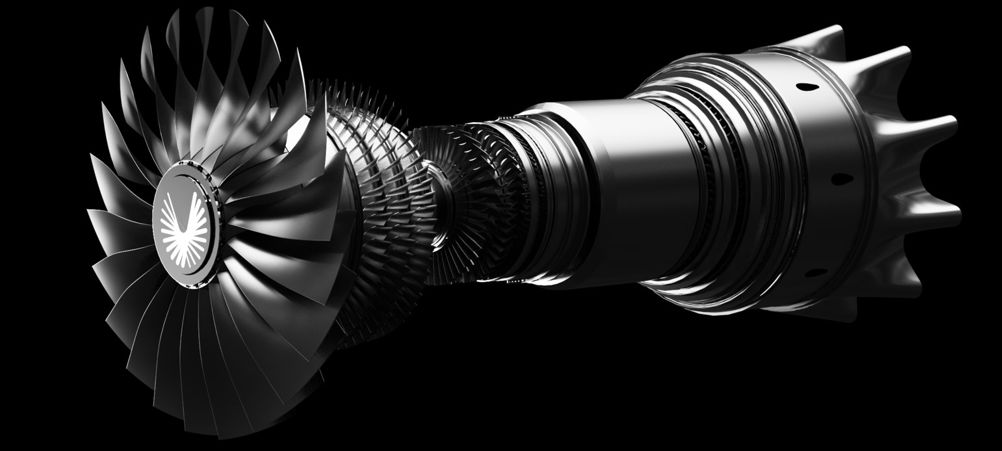

TF: Symphony is a new propulsion system optimised for environmentally and economically sustainable supersonic flight. Symphony will leverage proven technologies and materials to achieve optimal performance and efficiency. The bespoke engine is designed for sustainable supersonic flight and is designed to deliver 25 per cent more time on wing and provide 10 per cent operating cost savings to airline customers, when compared to derivative approaches.

Symphony’s technical specifications include two-spool, medium-bypass turbofan engine (no afterburner), 35,000lb thrust, optimised for 100 per cent sustainable aviation fuel (SAF), single-stage 72” fan, air-cooled, multi-stage turbine, and additive manufacturing that enables lightweight, low part count, and reduced assembly costs.

NT: We have done a few studies on our supersonic airliner propulsion system. We’re still in the debate of developing an engine from scratch with a partner or modifying an existing engine with a partner. Given the early stage of aircraft development, we’ve mostly focused on the airframe development with some notional engine performance data.

What fuel will your aircraft will use?

TF: Overture is designed from the ground up and optimised to run on 100 per cent sustainable aviation fuel (SAF). Boom will power Overture’s development, certification, and production flight tests using SAF. We have secured 10 million gallons of net zero carbon SAF per year from Dimensional Energy and AIR COMPANY for the duration of the Overture flight test program. While SAF is still scarce today, SAF production is on track to grow rapidly before the first Overture will fly passengers. The SAF industry is receiving billions of dollars in investment every year and will continue to scale exponentially.

NT: We are looking to use some drop-in SAFs. We have a partnership with carbon neutral fuel producer Twelve. We believe that for supersonic commercial transport to exist, it must be carbon neutral.

How will sonic boom be mitigated?

TF: Overture will have a landing and take-off noise output similar to today’s subsonic long-haul aircraft. This will include the Chapter 14 landing and take-off noise levels. When flying over land, Overture can fly significantly faster than subsonic commercial jets—about Mach 0.94, without breaking the sound barrier. This is about 20 per cent faster than subsonic flight. Globally, there are more than 600 profitable and mostly transoceanic routes on which Overture offers a compelling speedup. Without changes to today’s overland flight regulations, Overture will only break the sound barrier over water.

NT: We are using sonic-boom shaping techniques that have been researched by NASA for the past 60 years and finally implemented in the NASA X-59 shaped sonic boom demonstrator. You can see how our aircraft incorporates low boom design features, such as its long slender nose, a common characteristic of shaped sonic boom aircraft. Other aircraft features are considering sonic boom mitigation, such as the wing design and placement, tail configuration, propulsion system, and other features. Since the whole aircraft helps produce the boom, we need to make sure the aircraft is designed from tip to tail to meet boom loudness threshold.

What would be the best wing and fuselage configuration?

GG: Ultimately a supersonic aeroplane is going to look not unlike Concorde - it needs to be a thin round tube with a highly swept wing and engines built into the aeroplane overall, not outside the main shape in external nacelles that work very well for a subsonic aircraft, but will be very problematic in a supersonic aircraft that has to manage the complex interaction of shock-waves. Very likely however is that the internal design of future supersonic aircraft will be very different - the materials are likely to be much more sophisticated than the 1960s aluminium alloys of Concorde, the fuel system probably won’t be designed around unpressurised kerosene type fuels, and whilst still fly-by-wire, it’ll be a massively more sophisticated digital system than the very early analogue computing in Concorde.

PT: A single highly swept delta or ogive wing will support a balance between a wing that can produce enough lift and be strong and stiff with less volume and weight. Too thin though and there is less room to carry fuel so having some thickness can be mitigated with sweep to reduce the onset of wave drag. A slender fuselage that follows the area rule will still be used but tweaking will likely be done to reduce the drag around the wing-fuselage and other intersections.

What propulsion system would be suitable and is SAF viable?

GG: Firstly let’s kill the term “SAF” - the concept of “Sustainable Aviation Fuel” is a catch all for a wide range of kerosene-like liquids manufactured by a wide range of technologies, mostly biofuels, but none of them are genuinely net-zero. There are possible future technology “eFuels” that take CO2 from the air using renewable electricity, lock away some of that carbon and create synthetic fuels with the rest - those could be net zero, but that is far in the future still. Hydrogen combustion looks more promising but again we need a massive expansion of zero-carbon electricity generation.

PT: The propulsion system will likely make-or-break the market viability of any new SST. It needs to be economic enough in both subsonic and supersonic cruising. Adaptive cycle engines (engines that can operate with different bypass and pressure ratios) may help with the need for efficiency over a wide speed range and be an improvement over the turbojets and afterburners used in previous SSTs, which were inefficient in subsonic flight and significantly noisier. SAF is designed to be a “drop-in fuel” so there should be little issue with modern engines using it.

What is the best solution for the avoidance of sonic boom?

GG: Concorde tried to solve sonic booms simply by never flying supersonic over land, but even that wasn’t infallible as for example sonic booms were often heard in Cornwall from the Air France Concorde several hundred miles south-west on its way to Paris. NASA hope that their X59 QUESST research aircraft will show the way with a complex set of multiple wings and fins to control the interaction of shock waves, making what reaches the ground weak enough to be acceptable. However, it’s still far from certain that sonic booms really can be avoided.

PT: It will not be possible to avoid a sonic boom per se, only reduce its noise to an acceptable level. Generally, sonic booms caused directly by the aircraft will depend on the shape, volume, and lift (i.e., local pressure). Smooth surfaces with minimal slope changes will result in weaker shock waves. Long, slender fuselages will achieve this and distribute the wave strength across the body. Of course, being too slender puts constraints on the number of passengers.

When can we expect to be able to book a flight on a supersonic passenger aircraft?

GG: It’s far from sure yet that a viable supersonic transport can be economically or environmentally viable. But I do hope that, eventually, it will be. I hate saying that we only used to be able to fly faster than sound.

PT: The recent attempts at bringing new SST to market is very high risk and…has already seen several companies and projects fold. Boom seems to have been the most successful in the civilian passenger domain, having made several high-profile agreements with development partners and secured several rounds of funding. There seems to be enough progress being made [at Boom] to be cautiously optimistic they will achieve a final operational aircraft for major airlines first.

More on supersonic flight

- https://www.theengineer.co.uk/content/news/boom-and-rolls-royce-explore-propulsion-for-supersonic-overture/

- https://www.theengineer.co.uk/content/news/september-1946-the-miles-52-the-supersonic-aircraft-that-never-was/

- https://www.theengineer.co.uk/content/news/united-airlines-plans-sustainable-supersonic-passenger-flights/

Arriva makes £300m tri-mode train order with Hitachi Rail

This development shows up the lack of a comprehensive nationwide network of electrified lines for passenger services and freight The glacial speed of...